KR Strength chooses SolidPlant 3D

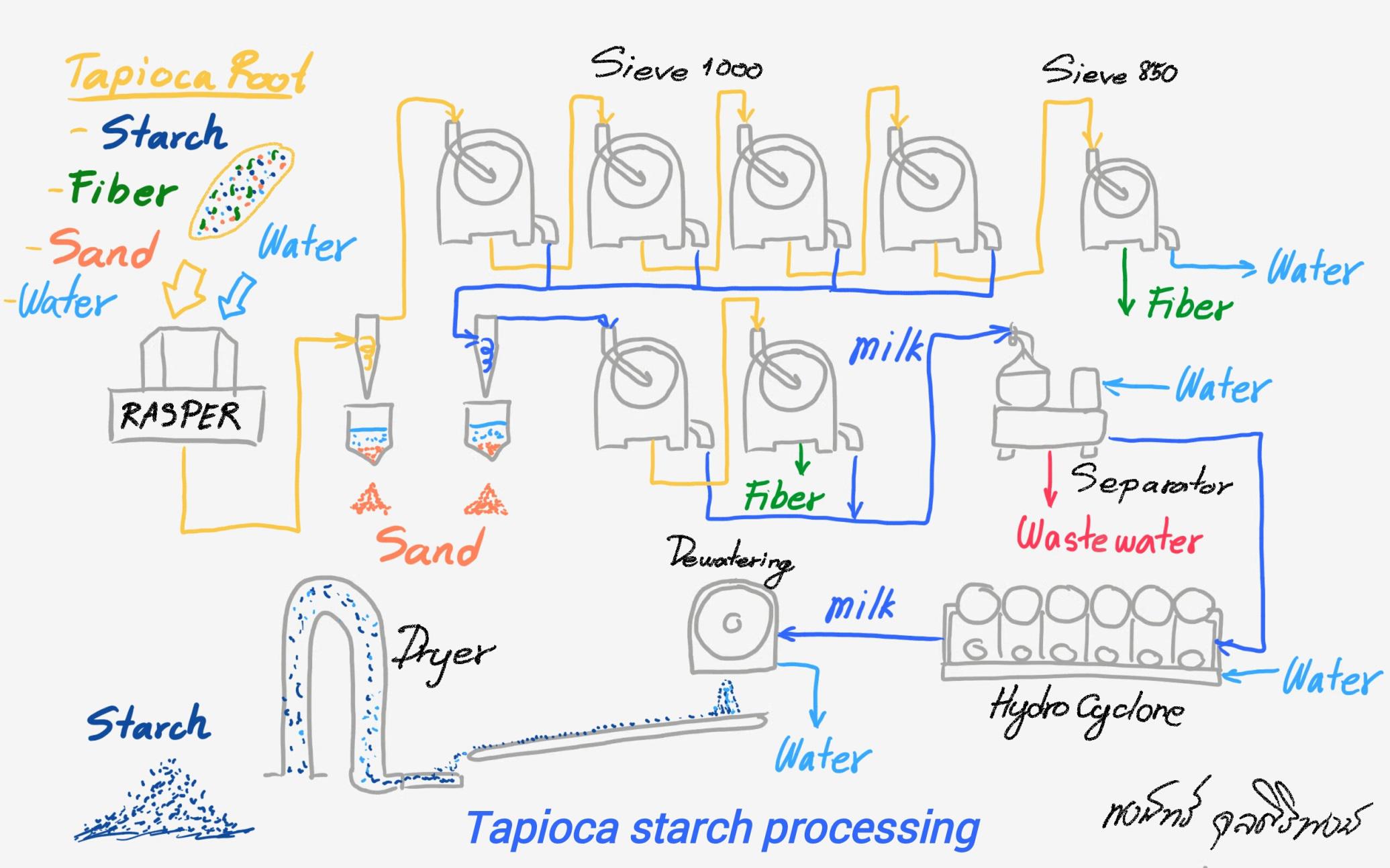

KR Strength is a machinery manufacturer based in Thailand. It produces machines, turn-key projects and plant lay-outs for the tapioca starch industry. Tapioca starch or tapioca flour is extracted from cassava (tapioca) root, and is used in the food industry.

The company has been designing their equipment in SolidWorks for many years. The pipe routing used to be done by using SolidWorks Routing, a feature of SolidWorks Premium. For the turn-key projects, the engineers used to draw the piping and instrumentation diagram (P&ID) in a 2D solution that did not connect with SolidWorks. When the 3D piping was being designed, a lot of time was spent on keeping the data between the 2D and 3D solutions in sync.

Vice president and in charge of the engineering department Mr.Pongtawi Junsiripong, first learned about SolidPlant when he visited his local reseller’s SolidWorks Innovation Day. He says:

“I was instantly impressed with SolidPlant’s ability to link the 2D schematics with the 3D design, knowing that this would save us a lot of time. But not only that, SolidPlant has very easy to use structural templates, and offers more advanced piping features than SolidWorks Routing does. It has the component catalogs that we need, and it can generate the documentation we send to our suppliers.”

Mr. Junsiripong was not worried about any problems that a transition to SolidPlant would cause:

“The facts that the user interface is very similar to that of SolidWorks, and that learning SolidPlant would not be a long process for our engineers who are used to SolidWorks made us feel confident about choosing this package. Moreover, having already designed our machines in SolidWorks, we found it very easy to import those existing models into the SolidPlant environment.”

KR Strength works closely together with their customers, using their feedback to improve the design of the products:

“We’re just the ones who make the machines, but the ones who use them will have better knowledge of the pros and cons of the machines and the lay-outs. The users can report back to us so we can improve the machines, change the lay-out, etc. From the feedback we can easily make revisions in the drawings and 3d model. SolidPlant makes it very easy to edit the model.”